A while back I got myself a 3D printer, and lets just say stuff happened and its hasn’t been setup until this summer. Being it took so long for it to get setup, my printer has become a little out dated, though it it still perfectly fine and pints well. Though, being a little older meant some interesting things for me, most of which have nothing to do with this post but maybe I’ll right about it one day. Today I’m writing about the Hotend of the printer.

My printer is a Taz 4 made by Lulzbot and was made in 2014 and the type of hotend it uses is call the Budschnozzle. This is not a great hotend but dose serve is purpose well enough, that is, until it burnt out.

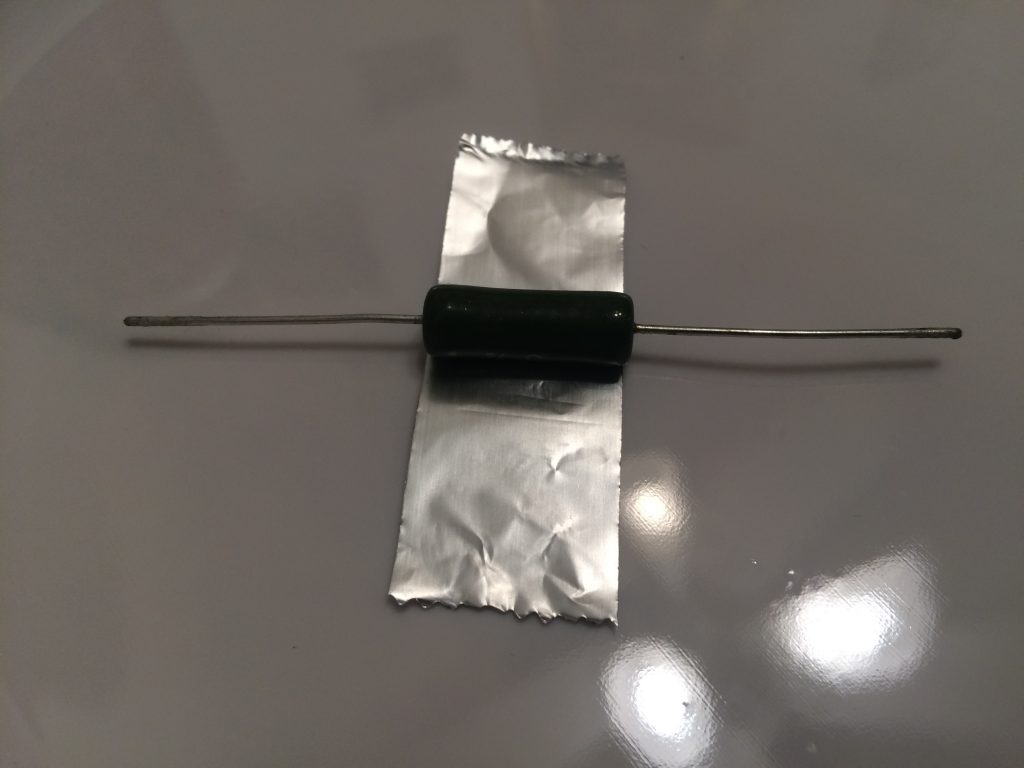

The Budschnozzle hotend uses a resister to heat itself up and not a Ceramic Heater Cartridge. This is not that big of a deal, but for me it became one when I went to print on day and the printer would not heat up. After troubleshooting for a little while and reading up online what to look for, I found that the heating resistor burnt out and needed to be replaced. I also found this was not an uncommon issue so once I was able to source a new resistor I bought two to make sure I’d have a spare.

When I went to replace the part however I noticed something interesting, which was the resister had a very sloppy fit in the hotend. To me, that would mean that the resistor would have a poor heat transfer as the heat its producing is not directly going into the hotend but first that air around it.

Now I’m going to preface this by saying this is not scientific nor had I done much research on this so I can’t say for sure what I did was good or bad, just that I have so far had no problems and everything is working well.

I had a thought that I could use some kind of thermal grease to help get the heat into the hotend and that maybe that would prevent the new resistor from burning out as it would transfer the heat it was producing into the hot end faster. I did a little bit of research and found two things. First if I where to using a thermal grease I should make sure it was non conductive or I needed to insulate the resistor to keep it from possibly shorting. Second, I needed a thermal grease that could hold up to the temperatures the printer can get to.

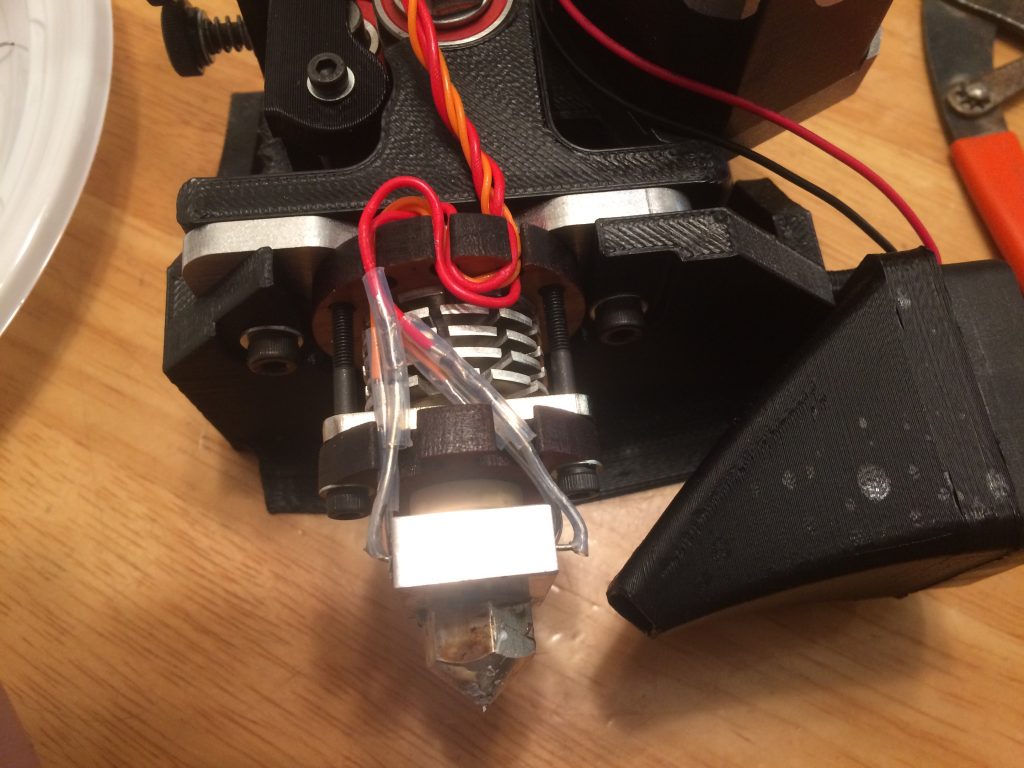

My first problem was pretty easy, I’d wrap the resistor in a little tinfoil. This would insulate the resistor and transfer heat well. The second problem also turned out to be pretty easy to fix. Normal computer thermal paste like ArticSilver is not rated for anywhere near the temperatures the printer is able to get to but something called Never Seize, or High Temperature Nickel Anti-Seize Lubricant made by Motorcraft has a high thermal conductivity and can withstand temperatures up to 2500F. I had some and so that’s what I used.

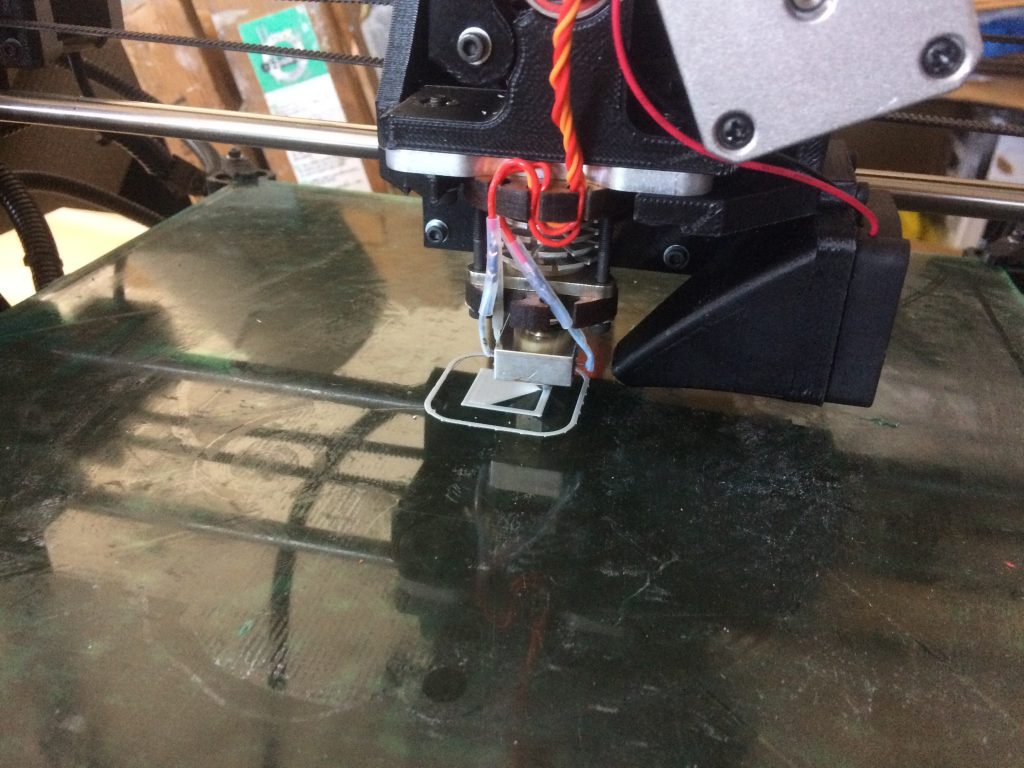

Getting it all put together was a little tricky as I didn’t want to make a mess but it all went back together nicely. I can’t say for sure if the printer is working better because of the change that I made but I do feel that the hotend heats up faster then it did before but I didn’t time it so I don’t know. What I do know it that the first time I heated up the printer there was a bit of the grease that needed to burn off so it smoked ever so slightly for a few minutes but its been fine ever since. I have been using the printer for over a week now and I have yet to have a problem, but if the resistor burns out again I have a replacement which should hold me over until I just upgrade my hotend.

Poor little resistor

Getting wrapped up

Little never seize

All back together

Hey I didn’t break it!